Welcome to Expresslube's Website

At Expresslube (UK) Ltd we specialise in the clean up and prevention of contaminated diesel and other hydrocarbon distillates found in fuel tanks on boats, stand-by generators storage tanks and on-highway / off-highway engine power equipment. New for 2012 is our hydraulic oil filtration service, oil filtration is nearly 50% less expensive than new oil and is environmentally conscious. As a company we have established a reputation for attention to detail, genuine customer commitment whilst providing competitively priced services and products.

Follow all the latest news within the industry, plus the services and products we provide.

Featured Products

1ltr Fuel Doctor

Excl. VAT:

£35.44

Incl. VAT:

£42.53

|

1ltr Rydlyme Marine Biodegradable Descaler

Excl. VAT:

£16.16

Incl. VAT:

£19.39

|

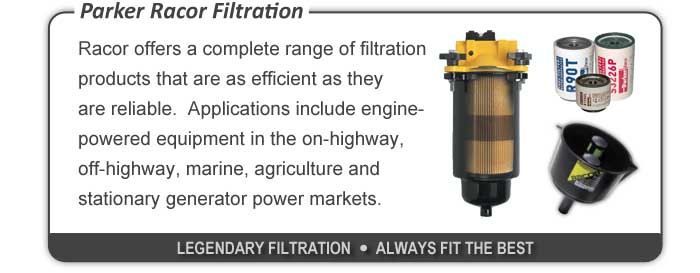

Racor 500FG Turbine Fuel Filter - See Thru BowlRRP: £396.10 OFFER: Excl. VAT: £264.07 Incl. VAT: £316.88

|

Racor Fuel Filter Funnel - RFF8C - 18.9 ltr/minRRP: £93.76 OFFER: Excl. VAT: £62.51 Incl. VAT: £75.01

|